Haiwang company is honored to receive the Digital Workshop Certification in Shandong Province! Intelligence propels high-quality development of enterprises.

Haiwang company is honored to receive the Digital Workshop Certification in Shandong Province! Intelligence propels high-quality development of enterprises.

On November 15th, the Department of Industry and Information Technology of Shandong Province announced the list of "2023 Shandong Province Intelligent Factories, Digital Workshops, Intelligent Manufacturing Scenes, and Intelligent Manufacturing System Solution Providers." Ocean King Corporation's "Digital Workshop for High-end Fluid Equipment Manufacturing" was recognized as a digital workshop in Shandong Province.

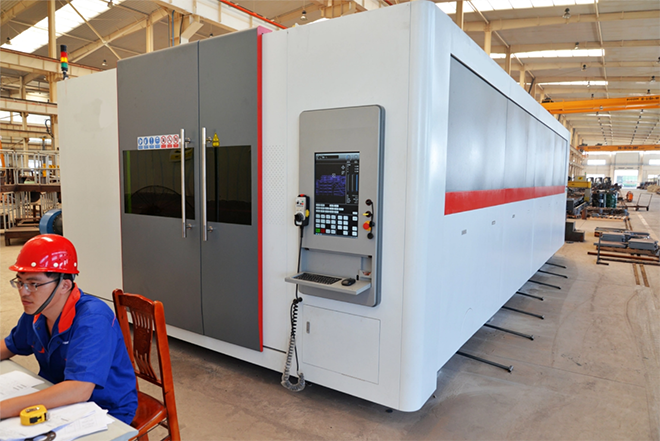

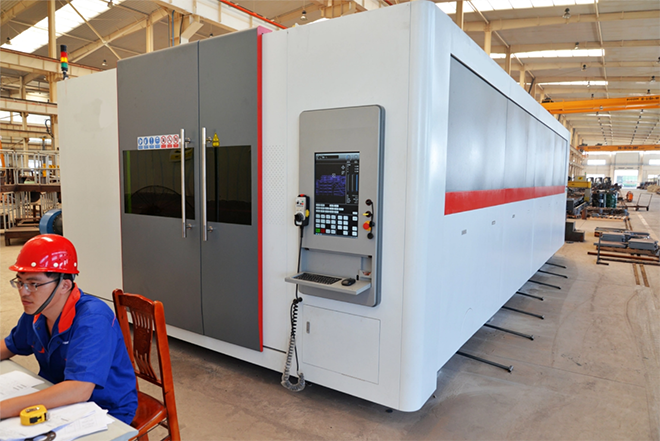

Haiwang company digital workshop for high-end fluid equipment manufacturing is a model project for the Industry 4.0 of fluid equipment manufacturing launched by the company under the guidance of "Made in China 2025." It integrates the new generation of information technology with the mechanical equipment industry, comprehensively builds a digital workshop, and accelerates the launch of the industrial integration of fluid equipment manufacturing.

The workshop includes production lines for swirl equipment machining and processing, as well as pumps, valves, and fluid equipment machining. More than 90% of the equipment is intelligent, and most of the core equipment achieves interconnection. The workshop has established an Enterprise Resource Planning (ERP) system, Advanced Planning and Scheduling System (APS), Manufacturing Operations Management System (MOM including MES, WMS, paperless workshop drawings), Intelligent Stereoscopic Warehouse System (WMS), Business Process Management System (BPM), Supplier Management System (SRM), Equipment Management System (EMS), and a visualization platform. This has comprehensively enhanced the intelligence level of various stages in the product lifecycle, including intelligent procurement and inspection of raw materials, production, quality testing and traceability, warehousing logistics, and more. At the same time, the adoption of digital technology integrates fluid manufacturing process systems with production management systems, thereby improving the level of process control technology for fluid equipment. This allows for comprehensive control of quality risks, process quality, energy conservation and emission reduction, and safety production, achieving the scientific and digital management of workshops and enterprise operations.

Through the construction of the digital workshop, production efficiency has increased by more than 30%; the product development cycle has been shortened by more than 20%; the defect rate of products has decreased by more than 50%; energy consumption has been reduced by more than 20%, and resource utilization efficiency has increased by more than 30%. Digitalization and intelligence empower high-quality development for the enterprise.